Reinventing 3D Printing — From Photons and Electrons to Matter.

NovaECAM engineers a new generation of advanced materials and components built directly from ions and light.

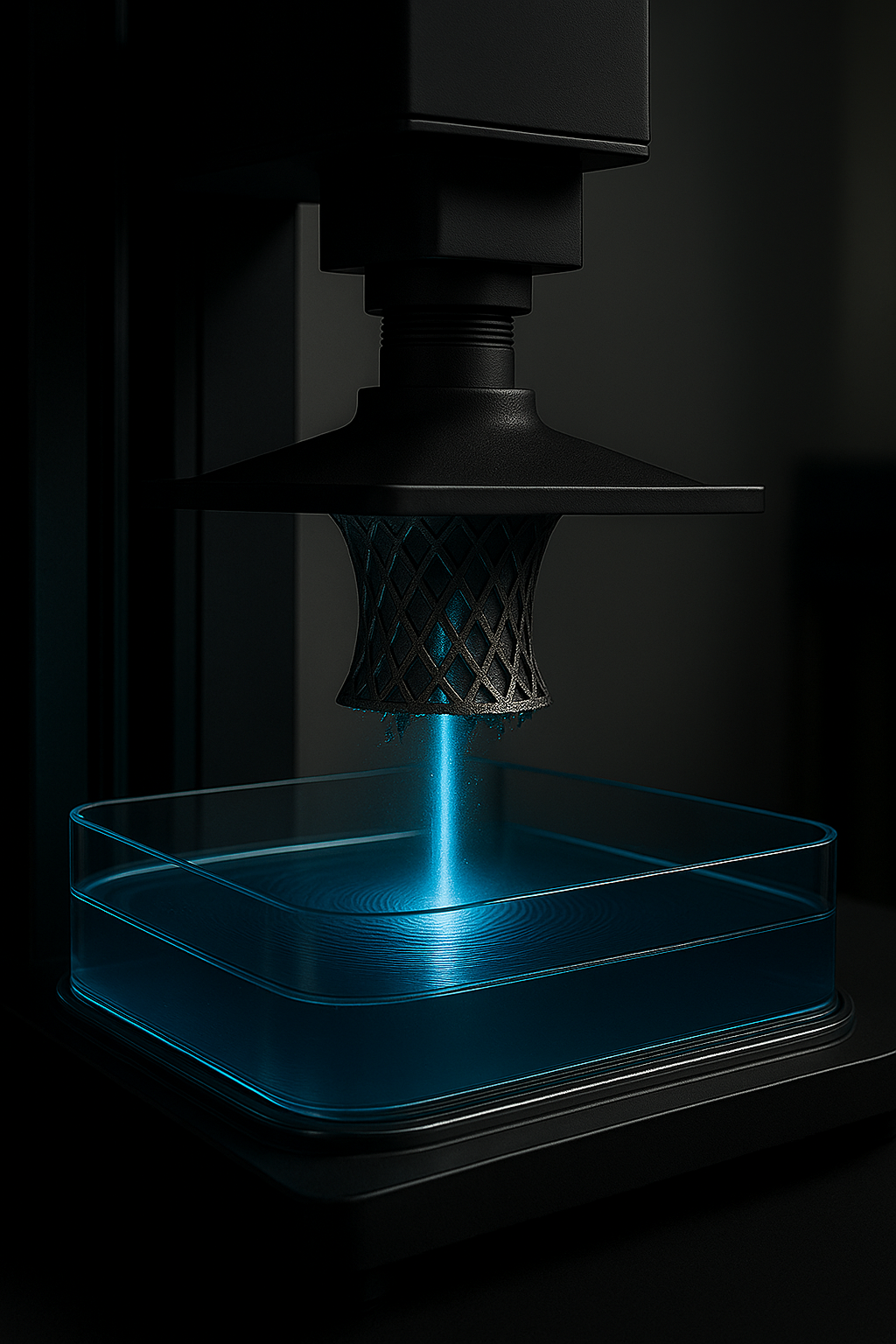

Our proprietary photo-electrochemical manufacturing process grows metals, dielectrics, and hybrid structures atom by atom, unlocking precision and functionality beyond any form of 3D printing.

We turn photons and electrons into matter — creating the foundation for the next era of manufacturing.

OUR CAPABILITIES

Transforming Light, Electrons, and Chemistry into Matter

NovaECAM delivers end-to-end advanced manufacturing and materials-engineering services based on our proprietary photo-assisted electrochemical additive manufacturing (PA-ECAM) technology.

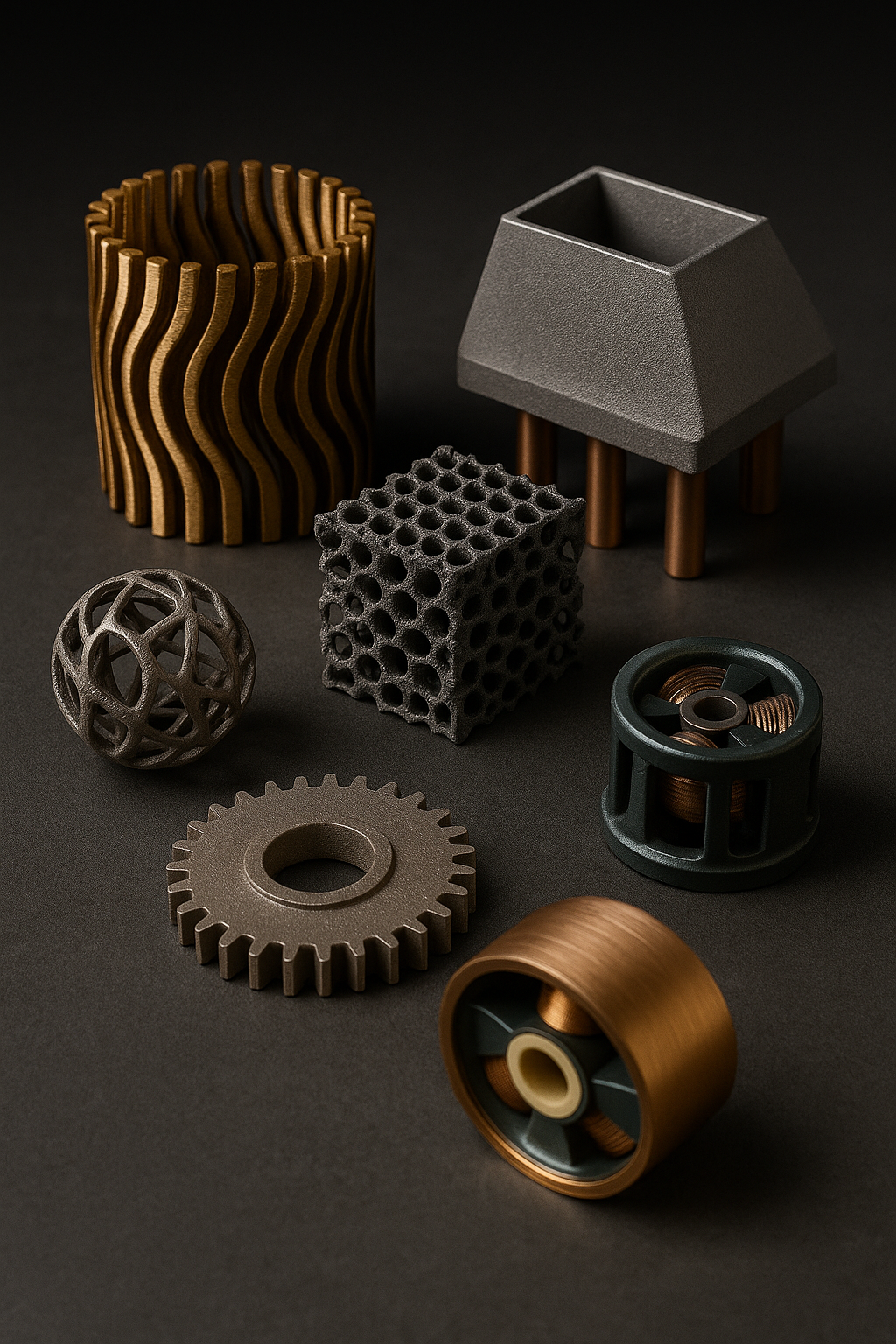

We don’t sell machines — we create finished, functional components and engineered materials that cannot be produced by any other manufacturing method.

Our technology combines the precision of optical lithography with the atomic control of electrochemistry, enabling formation of complex, multi-material structures with sub-25 µm resolution, zero thermal distortion, and nearly 100 % material efficiency.

NOVAECAM Technology Services

Precision Manufacturing and Materials Innovation

NovaECAM delivers high-performance components and advanced materials built with our proprietary photo-assisted electrochemical additive manufacturing (PA-ECAM) process.

We turn light, electrons, and chemistry into precision-engineered metal and hybrid structures — enabling breakthroughs in thermal management, electromagnetics, and multi-material design.

Our services range from concept development to full-scale component production.

-

We begin with your challenge — a cooling problem, magnetic requirement, or functional material target.

Our team evaluates how NovaECAM’s process can deliver a step-change in performance.Deliverables include:

Prototype samples built with custom electrolytes and photo-mediators

Validation of geometry, density, and composition accuracy

Initial performance data (thermal conductivity, magnetic response, or structural integrity)

Rapid turnaround for R&D and early-stage projects

Applications:

Micro heat pipes, gradient alloy coupons, test lattices, and dual-phase metal samples.Goal: Demonstrate feasibility and quantify the advantage of photo-electrochemical manufacturing.

-

Once feasibility is confirmed, NovaECAM produces fully functional components ready for integration into your systems.

We optimize process parameters, material chemistry, and internal architecture to meet your specifications.What we build:

Thermal management systems: loop heat pipes (LHP), vapor-chamber cores, and micro heat exchangers

Electromagnetic devices: NiFe or CoNi magnetic structures, inductive cores, and shielding meshes

Hybrid and gradient materials: Cu–Ni, Cu–Co, Sn–Ag, or custom multi-phase alloys

Embedded electronics: conductive networks and sensor architectures inside dielectric shells

Goal: Deliver production-quality prototypes with measurable thermal, magnetic, or structural performance gains.

-

For long-term programs and strategic partners, NovaECAM offers dedicated production and joint material development services.

Our team engineers custom electrolyte and photo-mediator systems to match your desired functionality, from thermal efficiency to magnetic permeability.Capabilities:

Serial production of precision micro-structured components

Tailored sulfate-based chemistries and photomediator design

Integration of AI-driven quality control and in-situ metrology

Confidential co-development agreements ensuring IP protection

Industries we serve:

Aerospace • Semiconductors • Energy Systems • Medical Devices • Automotive & e-Mobility • Advanced ResearchGoal: Provide end-to-end material and component production using NOVAECAM’s proprietary photo-electrochemical platform.

From Light to Function

Every NovaECAM part begins with light — and ends with performance that conventional manufacturing cannot achieve.

Contact Us

Let’s build the future of materials together.

Whether you’re exploring collaboration, investment, or custom component development — our team would love to hear from you.

Tell us about your application, your material goals, or the challenge you’re trying to solve.

A member of the NovaECAM engineering or business development team will connect with you shortly.

We partner with leaders in aerospace, electronics, energy systems, and advanced materials research — helping transform ideas into functional matter.